Wastewater Treatment Plants

Dutchland offers clients a unique combination of engineering and process design, operations expertise and control systems implementation to allow for efficient execution of all wastewater projects.

Typical Services:

- Turnkey Wastewater Engineering Services

- Complete Process Design, Permitting, Manufacturing, and Installation

- Complete Structural Design, Manufacturing, and Construction

- Complete Start-up/Equipment Operation

- Mechanical Equipment Installation

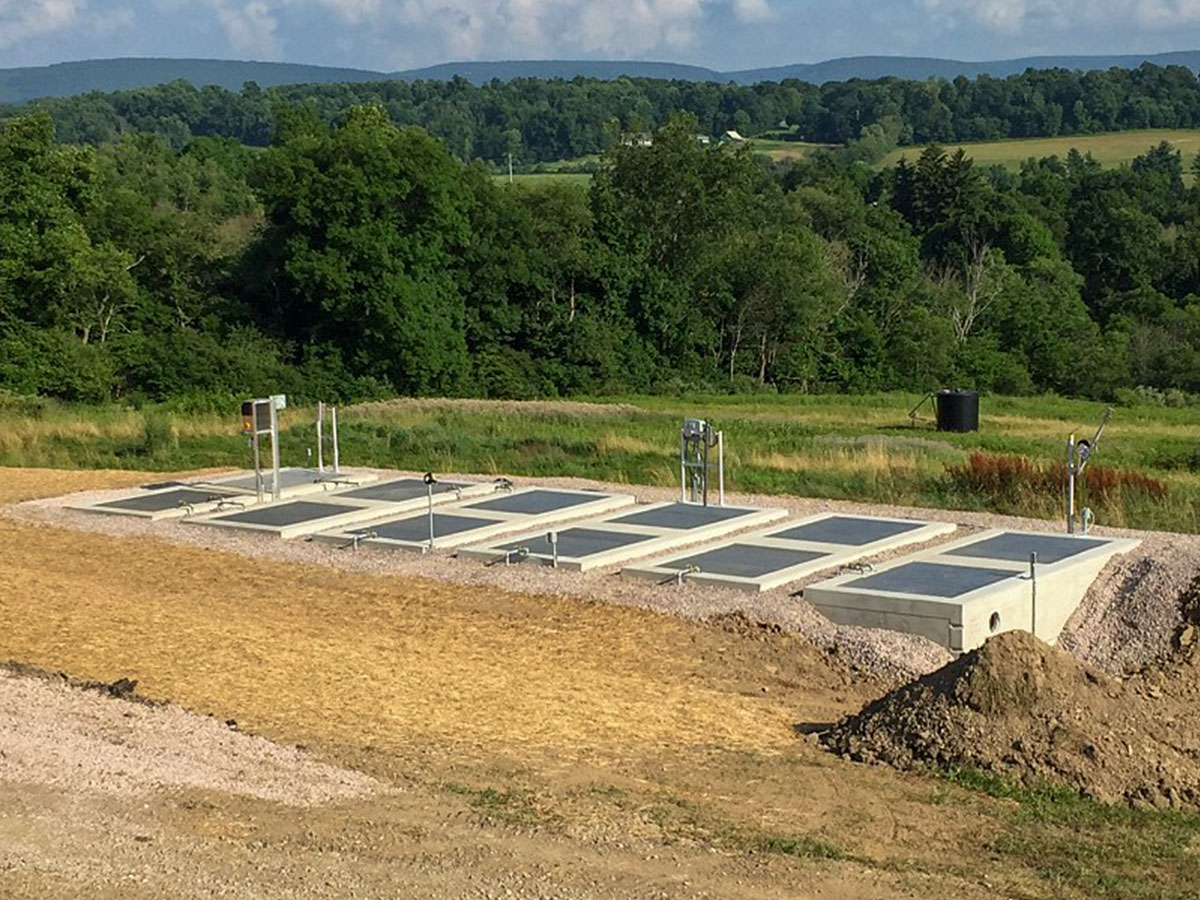

Turnkey Wastewater Treatment Plants

Our multi-disciplinary design team partners with each customer to develop tailored solutions for their unique wastewater needs.

Plants are designed to meet various limits, including: pretreatment, secondary treatment, tertiary treatment, and biological nutrient removal.

Additionally, Dutchland’s custom solutions for on-site treatment are contained in precast post-tensioned tanks which provide superior material benefits while requiring the lowest maintenance.

Tailored Solutions

- Pretreatment

- Secondary Treatment

- Tertiary Treatment

- Biological Nutrient Removal

The BIO-D Extended Aeration Solution

Effluent requirements from wastewater treatment plants continue to become more stringent. Biological Nutrient Removal (BNR), i.e. total nitrogen and phosphorous removal, has become a concern in many watersheds. Dutchland addresses BNR requirements by utilizing the BIO-D Extended Aeration Process.

Process

The BIO-D Process utilizes Modified Ludzaek-Ettinger (MLE) principals and incorporates dual environments of both oxic (aerated) and anoxic (non-aerated, mixed) conditions in separate stages of the plant. Nitrification is accomplished first, followed by denitrification. Nitrification occurs in the aeration tanks of the BIO-D process. A recirculation system is implemented to pump the nitrate-rich wastewater from aeration to the anoxic zone at the head of the plant. The anoxic zone receives all of the energy rich BOD from the influent wastewater as well as the recycled nitrate rich contents from the aeration tanks. The biological culture within the anoxic zone utilizes a portion of the BOD as a carbon food source, and the nitrates as a source of oxygen, as no oxygen is added in this zone. The nitrates are converted to harmless nitrogen in the process. Mixers in the anoxic zone provide the necessary suspension and mixing of the wastewater, and facilitate the release of the nitrogen gas bound within the wastewater to the atmosphere.

After approximately 24 hours in the aeration tank liquid flows into settling/clarification where separation of the solids and liquid occurs. In this phase there is no mixing; the liquids are kept perfectly still so suspended particles can settle and be recycled back to aeration to keep the bacteria population alive for continued treatment. This process of removing activated sludge and suspended particles from the liquid leaves a clear, highly treated water at the top of the chamber for discharge from the system. Following discharge from the clarifiers, effluent is disinfected by chlorine or ultraviolet disinfection.

For tertiary treatment a dual media sand filter is added after clarification. This tertiary treatment step allows the wastewater to be treated even further depending on effluent requirements.

Superior Process Performance

- Recycle rate designed for 400% of average daily flow

- Maximum dissolved oxygen levels of 0.5 mg/l are maintained in the anoxic tanks

- Minimum dissolved oxygen levels of 2.0 mg/l are maintained in the aeration tanks

- Total nitrogen level reduced to average monthly ranges of 6.0 mg/l to 8.0 mg/l

- Facilitates biological phosphorous reduction to provide greater level of phosphorous reduction while requiring less chemicals

- Phosphorous reduced to 0.5 mg/l or less

Advantages of the Bio-D Process:

Simplicity

Economical

Flexibility

Fast Installation

Produces high quality effluent

- BOD: 10 mg/l

- TSS: 10 mg/l

- Total Nitrogen: 8 mg/l

- Total Phosphorous: 0.5 mg/l

Advantages of the SBR Process:

Flexibility & Control

Economical

Small Footprint

Fast Installation

Sequencing Batch Reactor (SBR)

The Dutchland Sequencing Batch Reactor uses high quality precast concrete structures to handle all of the work of a continuous flow treatment system. All processes – biological oxidation, sedimentation, nitrification and denitrification occur in a single chamber. Multiple tanks are used in alternating sequence.

Process

The standard Dutchland SBR system consists of two SBR reactors, Influent Equalization, Sludge Holding, and Post Equalization (if downstream processes require a steady wastewater flow). The Dutchland SBR is a true fill and draw or batch process. The treatment cycle or phases follow the same pattern every cycle: Anoxic (mixed) Fill, Aerated React, Settle, Decant, and Idle.

The Anoxic Fill stage occurs when influent flow is fed to the individual reactor from Influent Equalization. Raw wastewater containing organics mixes with the biomass in the reactor. Only mixing (no aeration) takes place. Since there is little to no Oxygen available, the bacteria use the nitrate nitrogen as an electron acceptor. In this mode, denitrification takes place where the nitrate nitrogen is converted to nitrogen gas. This stage is comparable to an anoxic zone in conventional BNR activated sludge systems. The next phase of the treatment process is the aerated react phase. In this phase, mixing and aeration take place. In the aerated environment, the bacteria consume the BOD and Ammonia Nitrogen in the presence of Oxygen. This is where nitrification takes place which ultimately leads to the presence of nitrates which are consumed in the subsequent Anoxic Fill stage. In the settle phase quiescent conditions are provided. The aerators and mixing are turned off.

There is no influent wastewater fed to the SBR either, which would potentially interfere with settling.The Decant step is where treated wastewater is discharged from the SBR. To accomplish this, the Dutchland system uses a floating decanter. These decanters offer several advantages because the inlet orifice is always submerged below the water surface minimizing scum and floatables from being discharged. Sludge is wasted during the Idle Phase. In this phase, there is no mixing or aeration. The length of this phase depends on the operating strategy and amount of solids to be wasted. This phase also can be shortened or lengthened to buffer high influent flows.